automatic transfer machine is based on the principle of CNC machining development and design, very targeted, in the layout of the machine, rigidity, accuracy, and chip removal ability, than the flat bed CNC lathe has been significantly improved. Its advantages are mainly reflected in:

High machining accuracy: the transmission screw of CNC machine tool is a high-precision ball screw, the transmission gap between the screw and the nut is very small, but it does not mean that there is no gap, and as long as there is a gap, when the screw moves in one direction and then reverse transmission, it will inevitably produce reverse gap, and the reverse gap will affect the repeated positioning accuracy of CNC machine tool, thus affecting the processing accuracy. The layout of the automatic transfer machine can directly affect the clearance of the ball screw in the X direction, and the gravity directly acts on the axial direction of the screw, so that the reverse clearance during transmission is almost zero. The X direction screw of the flat bed CNC machine tool is not affected by axial gravity, and the gap cannot be directly eliminated. This is the inherent precision advantage that design brings to automatic transfer machines.

In the machinery manufacturing industry, the grade and ownership of CNC lathes is an important sign that reflects the manufacturing capacity of an enterprise! Whether CNC lathes can achieve the goal of high processing accuracy, stable product quality and improved production efficiency depends not only on the accuracy and performance of CNC lathes themselves, but also to a large extent, whether the operator can correctly maintain and use CNC lathes in production is closely related.

Conducive to chip removal: due to the relationship between gravity automatic transfer machine is not easy to produce winding tools, which is conducive to chip removal; At the same time, with the central screw and guide rail protection sheet metal, can avoid the accumulation of chips on the screw and guide rail.

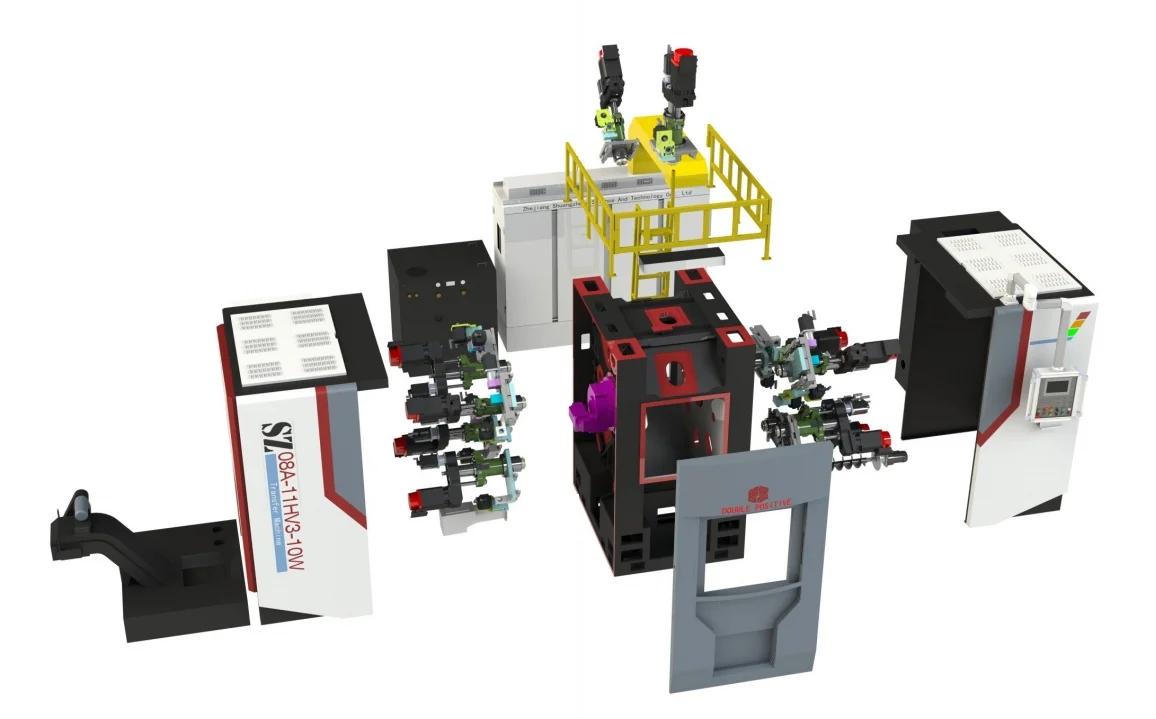

High degree of automation: the increase of tool number and the configuration of automatic chip removal machine are actually laying the foundation for automated production. One person on duty for multiple machine tools has always been the direction of machine tool development. Then add milling power head, automatic feeding machine or manipulator, automatic loading, one clamping to complete all the chip cutting process, automatic transfer machine, automatic chip removal, it becomes an automatic CNC machine tool with work efficiency. Although the flat-bed CNC machine can also increase the power milling head and automatic feeding, its structure is at a disadvantage in terms of automated production.

automatic transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html